Long-term engagement in integrated research on metallic materials and their surface protective coatings, with a focus on the mechanisms and applications of material surfaces and interfaces.

1. Stress-Hydrogen Coupling Effects on Service Behavior and Life Prediction of High-Strength Steel for Gears and Bearings

2. Hydrogen Damage Mechanisms and Material Development for Hydrogen-Blended Combustion Engine Components

3. Effects of Arsenic on Microstructure and Properties of Ultra-High-Strength Steel

4. Design and Service Behavior of High-Strength and Tough Protective Coatings

1. Significant achievements have been made in preparing high-strength and tough coatings, researching substrate damage induced by coating cracking, and developing hydrogen embrittlement-resistant metallic materials. The theory of coating-induced cleavage cracking in ductile metallic substrates has been proposed, and a protective method against substrate damage caused by coating cracking has been established.

2. These advancements have significantly improved the fatigue resistance of coated metallic materials and resolved the technical challenge of brittle cracking in coated metallic structural components. Furthermore, a theoretical framework for deep hydrogen traps formed by misfit dislocations at semi-coherent interfaces has been developed, enabling the controllable preparation of high-density and uniformly distributed deep hydrogen traps. A series of high-strength and tough hydrogen-resistant steels, including heavy-haul railway wheel steel, spring steel, and marine equipment steel, have been successfully developed. The overall research technology has reached an internationally leading level.

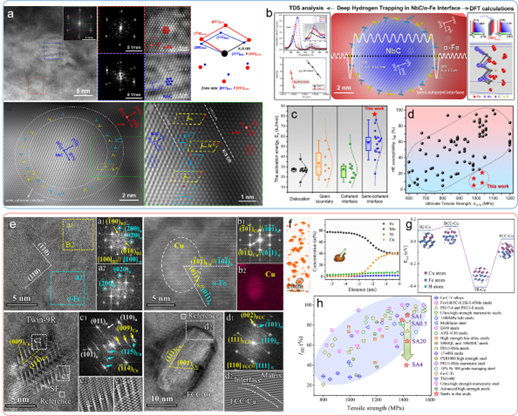

Fig.1. (a) High-resolution transmission electron microscopy (HRTEM) analysis of NbC and the Fe matrix, indicating a K–S semi-coherent orientation relationship between NbC and α-Fe, with two sets of misfit dislocations, b(1) and b(2), present at the semi-coherent interface. (b) Thermal desorption spectroscopy (TDS) experiments combined with density functional theory (DFT) calculations reveal that misfit dislocations are the essence of hydrogen traps. (c) Comparison of deep hydrogen trapping capabilities of NbC with other defects. (d) Comparison of hydrogen embrittlement susceptibility. (e) HRTEM images and fast Fourier transform (FFT) analysis of B2-Cu, BCC-Cu, 9R-Cu, and FCC-Cu precipitates in the Fe matrix. (f) Three-dimensional atom probe tomography (3D-APT) analysis of the composition of 9R-Cu precipitates. (g) DFT calculations demonstrate that semi-coherent 9R-Cu precipitates exhibit stronger hydrogen trapping capabilities. (h) Comparison of hydrogen embrittlement susceptibility, showing that martensitic stainless steel containing 9R-Cu precipitates exhibits the best resistance to hydrogen embrittlement.

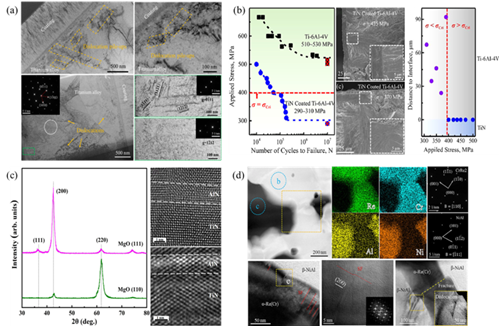

Fig.2. Fundamental characterization of fatigue failure mechanisms: (a) Cross-sectional morphology of the alloy matrix interface after fatigue testing at 600 MPa, (b) S-N curve, fatigue fracture morphology, and fatigue crack initiation diagram, (c) XRD pattern of the material and HRTEM image of the interface with <200> orientation, (d) Microstructural image of the coating after fatigue testing at 350 MPa, highlighting the diffusion barrier layer.

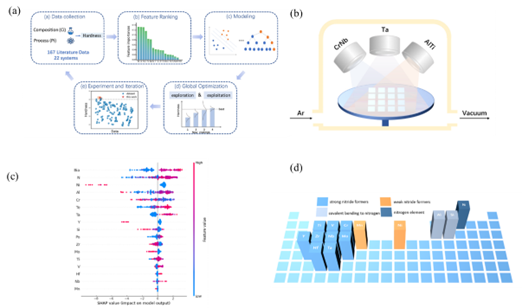

3. A material design strategy combining machine learning and high-throughput experiments is proposed to rapidly screen ultrahard high-entropy ceramic coatings. The composition and process parameters of the coating are used to predict the hardness. The coating hardness predicted by this method is 9% higher than in the quinary system from the original training dataset. These coatings were successfully synthesized through high-throughput experiments. Machine learning combined with high-throughput experimental methods can effectively accelerate the composition design of multi-component materials.

(a) Schematic design of a high-entropy ceramic coating with high hardness, (b) Schematic diagram of magnetron co-sputtering process,(c) Global interpretation using SHAP,(d) Elemental components of high-entropy nitride coatings, including strong nitride formers, weak nitride formers, and p-elements that form a covalent bond with N

1. Zhang Binglu, Zhu Qisi, Xu Chi, Li Changtai, Ma Yuan, Ma Zhaoxiang, Liu Sinuo, Shao Ruiwen, Xu Yuting, Jiang Baolong, Gao Lei, Pang Xiaolu, He Yang, Chen Guang, Qiao Lijie. Atomic-scale insights on hydrogen trapping and exclusion at incoherent interfaces of nanoprecipitates in martensitic steels, Nature Communications, 2022, 13.

2. Chen Yanmeng, Yan Xueyan, Guo Tao, Ma Yuan, Mi Zhishan, Pang Xiaolu, Qiao Lijie. Cross-interface growth mechanism of nanotwins in extremely high stacking-fault energy ceramic layer, Acta Materialia, 2023, 257.

3. Yang Sen, Guo Tao, Yan Xueyan, Gao Kewei, Pang Xiaolu. High-density twin boundaries in transition metal nitride coating with boron doping, Acta Materialia,2023,255.

4. Sun Huili, Lv Wenting, Yang Yu, Li Dongdong, Yan Luchun, Pang Xiaolu, Gao Kewei. Optimizing the hydrogen embrittlement resistance by tuning the structures of Cu-rich nanoprecipitates in high strength martensite stainless steels, Acta Materialia, 2023,246.

5. Shi Rongjian, Fu Hui, Chen Kaixuan, Sun Wanting, Wang Zidong, Qiao Lijie, Yang Xusheng, Pang Xiaolu. Combining synergetic effects of gradient nanotwins and nanoprecipitates in heterogeneous bronze alloy, Acta Materialia, 2022, 229.

6. Bai Yanyun, Guo Tao, Wang Jiawei, Gao Jin, Gao Kewei, Pang Xiaolu. Stress-sensitive fatigue crack initiation mechanisms of coated titanium alloy, Acta Materialia, 2021, 217.

7. Shi Rongjian, Ma Yuan, Wang Zidong, Gao Lei, Yang Xu-Sheng, Qiao Lijie*, Pang Xiaolu. Atomic-scale investigation of deep hydrogen trapping in NbC/alpha-Fe semi-coherent interfaces, Acta Materialia, 2020, 200.

8. Xu Zhao, Liu Saiyu, Geng Pu, Shi Rongjian, Gao Kewei, Pang Xiaolu, The hydrogen embrittlement mechanisms and hydrogen induced cracking process of selective laser-melted GH4169, Corrosion Science, 2023, 224.

9. Zhu Yujie, Guo Tao, Geng Pu, Yu Haiyuan, Wu Yajing, Gao Kewei,Pang Xiaolu, Research on oxidation kinetics of CoNiCrAlY coatings in pure steam environment, Corrosion Science, 2023,224.

10. Wang Jiawei, Guo Tao, Chen Yanmeng, Wang Xiaobo, Geng Pu, Gao Kewei, Pang Xiaolu. Significant improvement in fatigue life of titanium alloy induced by superlattice Coating, International Journal of Fatigue, 2023, 167.

1. Pang Xiaolu, Wu Shaoyu, Method and Device for Real-Time Detection of Thin Film Crack Spacing, 2022-08-02 to 2041-08-10, China, CN202110915135.0.

2. Pang Xiaolu, Shi Rongjian, Lu Lanying, Li Jingchuan, Feng Xinyi, Qiao Lijie, Wang Zidong, Nanostrengthened Hydrogen Embrittlement-Resistant Steel and Preparation Method Thereof, 2021-06-11 to 2040-01-03, China, CN202010006344.9.

3. Gao Kewei, Tan Linhao, Li Dongdong, Xu Qiufa, Pang Xiaolu, Yan Luchun, Heat Treatment Method for Improving Hydrogen Embrittlement Resistance of Martensitic Stainless Steel, Stainless Steel, and Applications, 2022-08-19 to 2041-11-19, China, CN202111402466.0.

4. Pang Xiaolu, Guo Tao, Gao Kewei, Forming Nanotwinned Regions in a Ceramic Coating at a Tunable Volume Fraction, 2022-08-19, United States, 20230015174.

5. Pang Xiaolu, Shi Rongjian, Lu Lanying, Li Jingchuan, Feng Xinyi, Qiao Lijie, Wang Zidong. A nano-enhanced steel with hydrogen embrittlement resistance and its preparation method, 2021-06-11,China, CN20201006344.

1. First Prize of Metallurgical Science and Technology Award (2022)

2.16th China Youth Science and Technology Award

3. First Prize of Natural Science Award of the Ministry of Education (2021)

4. First Prize of Science and Technology Progress Award of the Chinese 5. Society for Corrosion and Protection (2017)

6. Member of the Chinese Materials Research Society (CMRS)

7. Member of the Chinese Society for Corrosion and Protection (CSCP)

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026